- YNN

- China

- 5-35days

- 50 sets/months

Feature:

1. Oil Filter Machine is mainly used for filtering series kinds of plant crude oil, such as peanut, sesames, rape-seeds, sunflowers, coconut oil, palm kernel oil, etc.

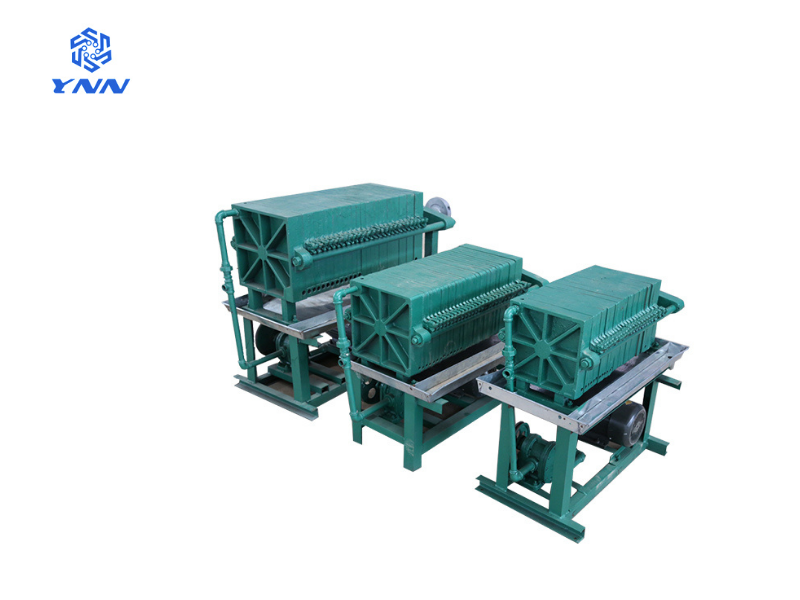

2. Capacity customized from customer's request, suitable for different scales of oil refinery and oil factory.

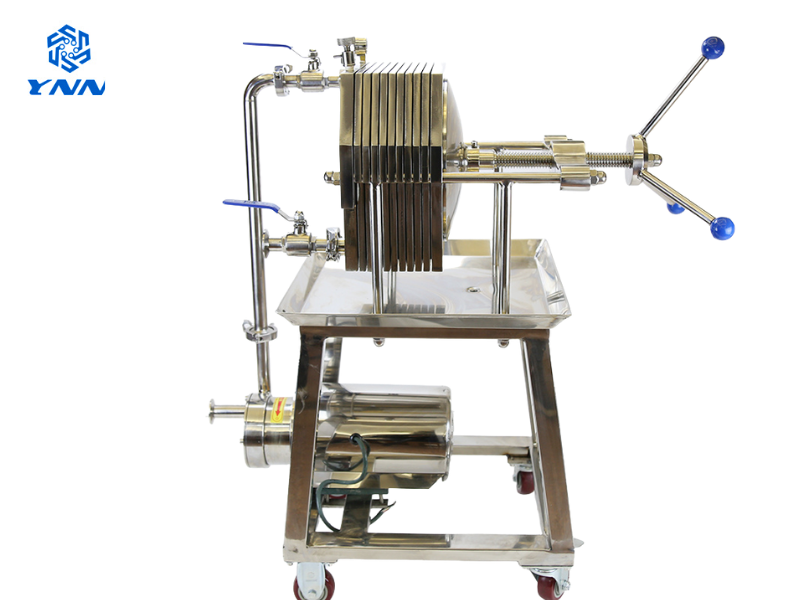

3. Oil Filter Machine is equipped with gear pump which convey the oil to the filtratrition rooms, saving labor and has higher efficiency.

4. Light weight, convenient operation, matched with oil pump and motor.

Oil Filter Machine Introduction:

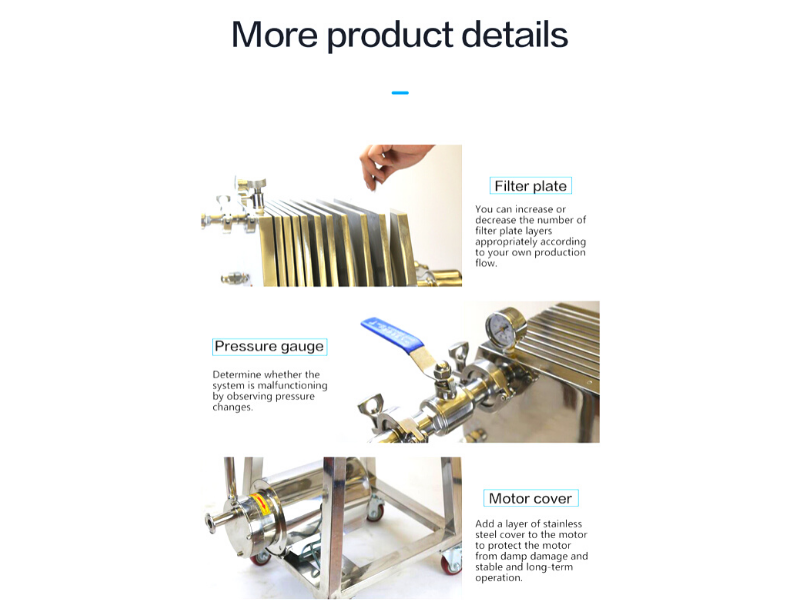

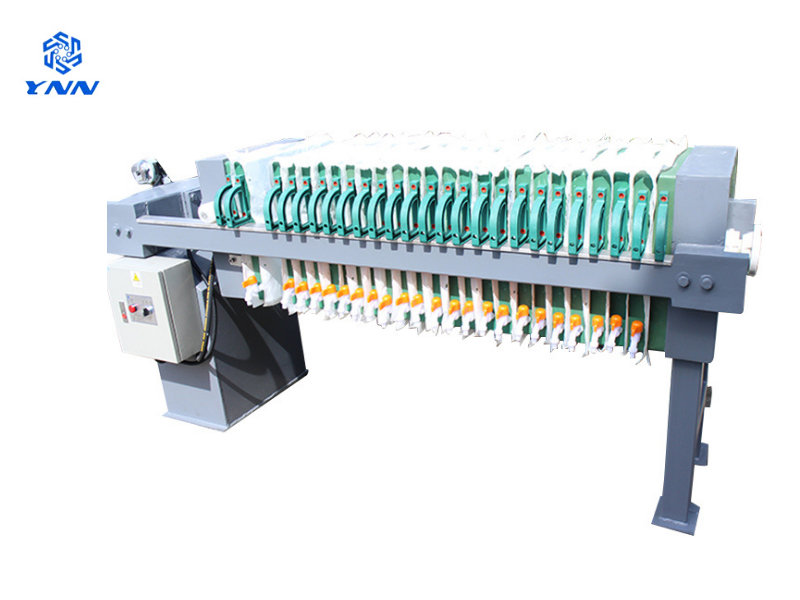

Stainless steel plate and frame filter press adopts 304 or 316L superior stainless steel materials for the manufacture. This frame oil filter is composed of filter plates, filter frames, oil pump and filter cloth, etc.

When the crude oil is pumped into the filtering machine, under the different pressure in and outside the machine, the crude oil go through the filtering cloth and come out from the pipe under the filter plate, while the oil dregs remains on the surface of the filtering cloth,thus realizing the filtering process.

Oil Filter Machine Advantages:

1. Oil Filter Machine is used in pharmaceutical, food, beverage, water treatment, brewing, petroleum, chemical, anti-corrosion, environmental protection and other industries, is all kinds of liquid filtration, clarification, purification, sterilization treatment of the latest equipment

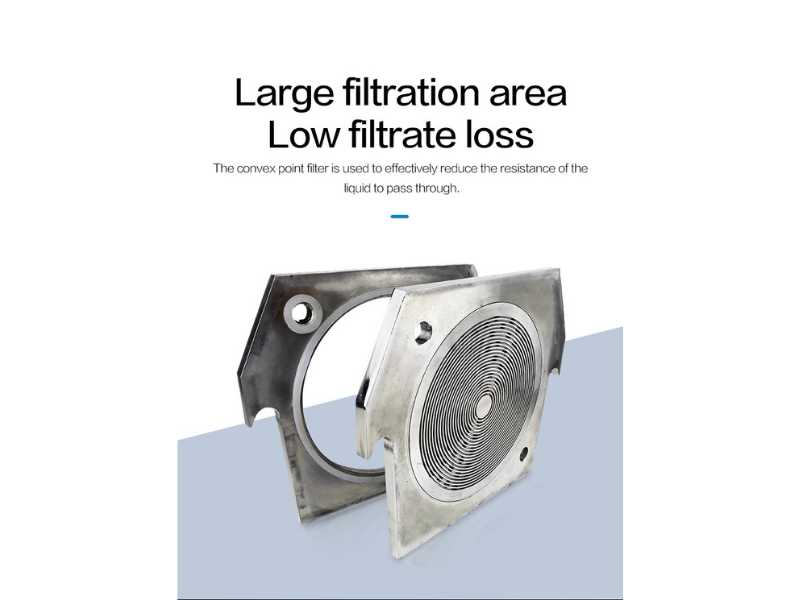

2. Use of bump-type filter plate, increasing the water cross-sectional area, reducing the liquid filtration, flow resistance, the flow of any improper liquid dead angle, to maintain the stability of liquid properties, bump filter plate filter material , Filter paper, etc.) is not easy to break, to extend the service life of various media

3. All the sealed parts of all installed (milky silicone rubber seals, non-toxic high temperature) no leakage, that is, in the filter box on the positive and negative sides, import and export of double-folding ring and other sealing parts are installed circular ring

4. Oil Filter Machine can be filtered liquid according to the different production processes (primary filtration, semi-fine filter, fine filter) requirements, the replacement of different filter users according to the size of the production flow, a corresponding reduction or increase filter frame material

5. When the filter work, pressing the seal ring, no loss of liquid, liquid clarity, and sterilization selection of microporous membrane filter, sterilization effect is particularly good.